The use of plasma gasification technology in treatment of municipal solid waste is one the rise. Plasma gasification for extraction of renewable fuels from landfills is still a relatively new process. Plasma gasification itself is not a new technology, though until now it was solely used to treat different types of hazardous waste like chemical weapons and incinerator ash. The process allows the decomposition of toxic chemicals in hazardous waste to nonhazardous slag.

Plasma gasification enables the extraction of recyclable substances and materials from waste with hardly any environmental impact. Plasma gasification also transforms and extracts carbon based materials and turns them into high octane fuels. This gives a whole new meaning to rubbish removal practices, and reduces the amount of waste ending up in landfills – a problem that’s growing bigger by the day, literally. The process, also known as plasma arc processing can potentially help countries achieve zero waste without any bad emissions or ill effects for the environment. This particular method is much more efficient than other pyrolysis technologies as it achieves nearly hundred percent conversion rate for carbon-based materials.

Plasma gasification enables the extraction of recyclable substances and materials from waste with hardly any environmental impact. Plasma gasification also transforms and extracts carbon based materials and turns them into high octane fuels. This gives a whole new meaning to rubbish removal practices, and reduces the amount of waste ending up in landfills – a problem that’s growing bigger by the day, literally. The process, also known as plasma arc processing can potentially help countries achieve zero waste without any bad emissions or ill effects for the environment. This particular method is much more efficient than other pyrolysis technologies as it achieves nearly hundred percent conversion rate for carbon-based materials.

The two main products derived from waste conversion by using plasma gasification are syngas and slag. Syngas is a simple fuel gas that can be combusted directly (in engines and generators) or it can be refined and combined with other gases to produce high grade fuels and useful chemicals needed by industry and manufacturing. The other product – slag, resembles glass and is the cooled, solidified leftover of burning waste. Slag becomes nontoxic after plasma gasification. Being tightly bound and nontoxic, leftover slag is suitably used as a basic construction material.

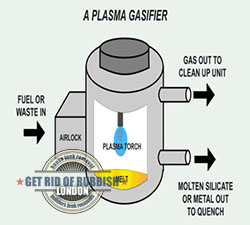

Although a multi stage process, plasma gasification is relatively straightforward. The whole process begins with feed input i.e. feeding the plasma torch system with various types of organic, non-organic, hazardous and nonhazardous waste. The next stage is to homogenise and dry the feed input, during this stage any useful materials and substances are extracted from the feed input waste. The next stage is where things heat up – the homogenised waste mass is subjected to extreme heat of the plasma torches inside sealed, pressurised machine called a reactor. It is during this step that carbon-based materials break down and become fuel, and inorganic waste melts down to slag, which is then extracted and cooled off. During the burning process, all toxic substances, poisons and hazards are literally burnt to nothing. The next step is harvesting and purification of the newly formed gas – during this stage gases are refined and turned into basic fuel which is then mixed or refined further to produce high-octane renewable fuel. The heat from the plasma gasification process is turned into steam and pumped back into the system as means of propulsion for some of its functions.

Plasma gasification can produce a variety of useful materials and substances. Apart from renewable fuels and construction materials, gasification can be used to generate electricity, different polymers, hydrogen and useful chemicals. It is expected for plasma gasification to grow in popularity and to become one of the main recycling technologies.